The GNU-Octave® scientific programming language (to define the script and parametrize the simulation) is used to operate the coupling between analytical calculations and FEA approaches (Figure1). Its postprocessor is used to calculate the AC losses according the ripple of current at the specified frequency.

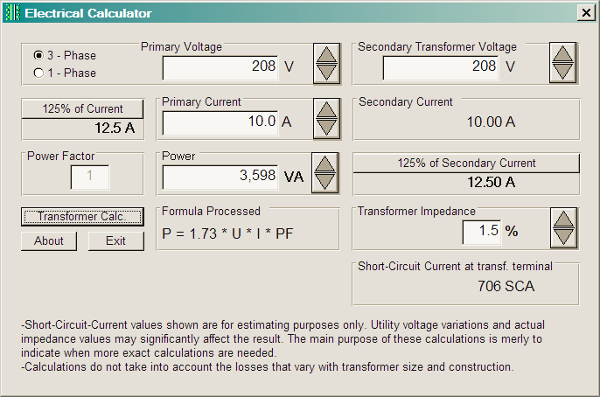

TRANSFORMER WINDING CALCULATION SOFTWARE SOFTWARE

To be quick and with no license fees, the FEMM® software has been selected to quickly solve the Maxwell’s equations in 2D and show the impact of frequency effects in conductors. With the switching frequency increase in converters, the phenomena causing additional copper loss in windings are well identified, but their impact is difficult to solve analytically for real components without using important hypotheses or time-consuming 3D model introduction in FEA software at first. Analytically, the DC copper and core losses can be already estimated from well-known models by robust analytical calculations. Globally, the problem is introduced on a Mathcad® page with all the requirements about the operation (buck/boost/filter choke, flyback/ bridge transformer…) and its related electrical values as well as with the first estimated set of dimensions, turns and conductors to calculate the DC resistance, RMS current and flux density values. Building the model with an automatic generation also permits to reduce the risk of human errors in the geometric construction or in the input data. The main interest of the presented method is to estimate easily and cheaply in an automatic way the additional losses in a magnetic component. To answer to this concern, a new fast and cheap v will be presented. However, from an industrial point of view, the cost of such software and the time spent to build each mechanical model remain a limitation.

Another way to estimate their amount can be the use of Finite Elements Analysis simulation (FEA).

Of course, it exists some analytical models to estimate their level, but they remain quite complex or require many hypotheses for an easy and accurate application in the Industry. Nevertheless, a higher switching frequency brings new problematics for the magnetic components design.Īdditional losses due to skin-depth reduction, proximity effect between conductors or fringing flux effect can become very important to be fully considered. This is impulsed by the development of semiconductors in GaN and SiC technologies which permit to obtain the most efficient converters in the smallest size. The current trends in power electronics tend towards higher frequencies to reduce the weight and volume of passive components.

0 kommentar(er)

0 kommentar(er)